What Are The Disadvantages Of Welded Wire Mesh - Custom Wholesale

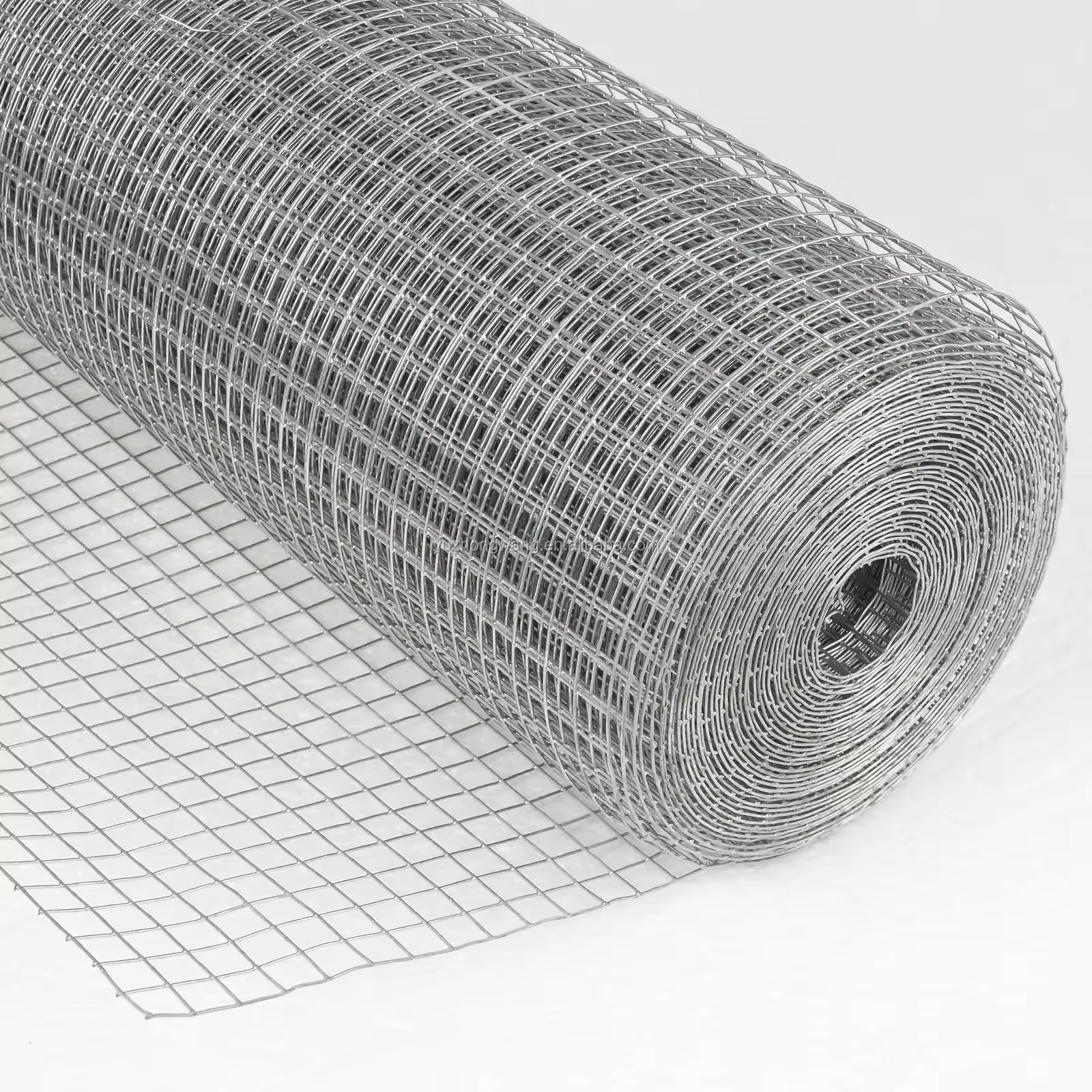

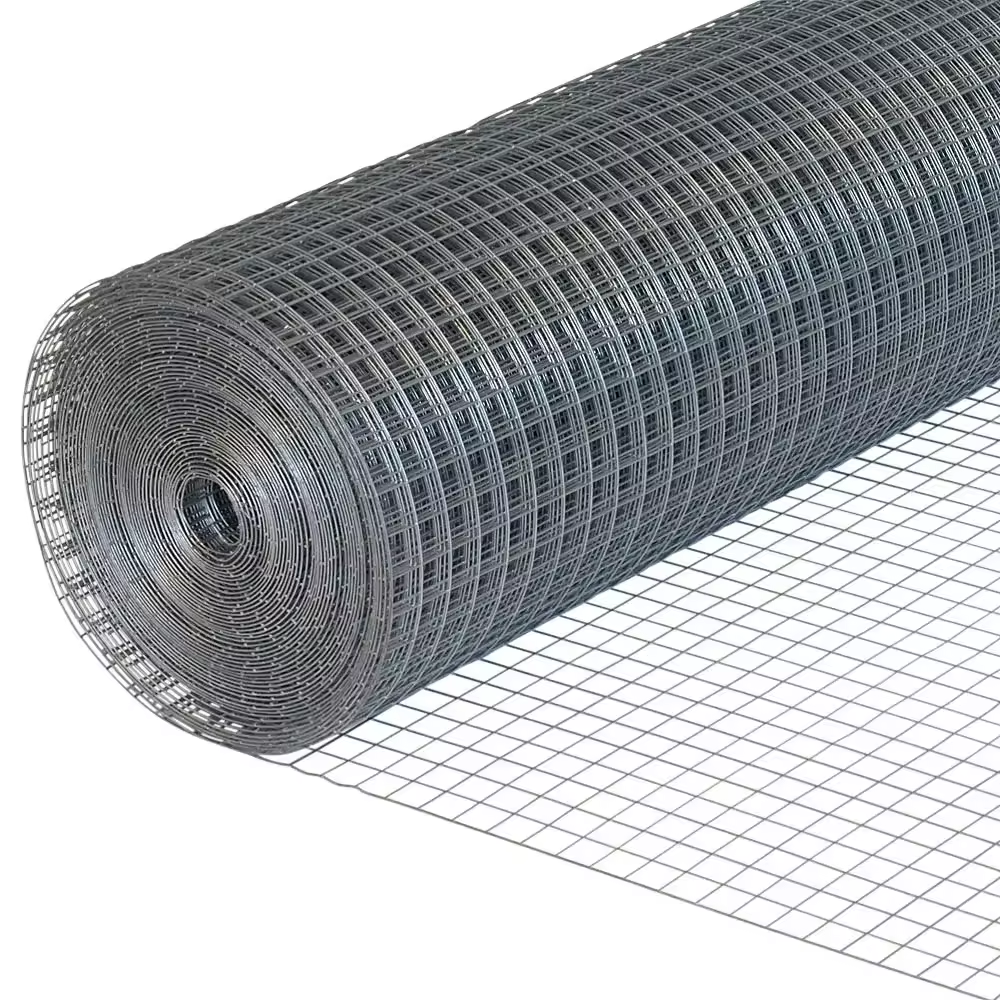

In the realm of construction and industrial applications, welded wire mesh serves as a versatile solution for various structural needs. However, despite its widespread use and popularity, welded wire mesh is not without its drawbacks. Let's explore the disadvantages of welded wire mesh and how Beifang, a trusted brand in the industry, addresses these challenges with its custom 2x2 galvanized steel welded wire mesh solutions.

One of the primary disadvantages of welded wire mesh is its susceptibility to corrosion, especially in harsh environmental conditions or corrosive atmospheres. Standard welded wire mesh may deteriorate over time, compromising its structural integrity and longevity. However, Beifang's custom 2x2 galvanized steel welded wire mesh offers enhanced corrosion resistance, thanks to its galvanized coating. By applying a protective zinc layer, Beifang ensures that its wire mesh withstands corrosion, prolonging its lifespan and maintaining structural stability even in challenging environments.

Another drawback of welded wire mesh is its limited flexibility and adaptability to complex shapes and designs. Traditional welded wire mesh often comes in standard sizes and configurations, making it challenging to meet the unique requirements of specific projects. Beifang addresses this limitation by offering custom solutions tailored to the precise dimensions and specifications of each application. Whether it's a unique shape, size, or mesh pattern, Beifang's custom manufacturing capabilities enable clients to achieve optimal results without compromising on quality or performance.

Additionally, welded wire mesh may exhibit welding defects such as incomplete fusion, weld spatter, or excessive distortion, which can affect its structural integrity and aesthetics. Beifang employs stringent quality control measures and utilizes advanced welding techniques to minimize defects and ensure consistency in every wire mesh product. Through meticulous craftsmanship and attention to detail, Beifang delivers welded wire mesh of the highest quality, free from imperfections and defects, guaranteeing reliability and durability in every application.

Furthermore, the rigidity of welded wire mesh can pose challenges during installation, especially in curved or irregular surfaces where flexibility is required. Beifang's custom 2x2 galvanized steel welded wire mesh offers enhanced flexibility without compromising on strength or stability. With its precision-engineered design and superior materials, Beifang's wire mesh conforms seamlessly to complex contours and shapes, facilitating hassle-free installation and ensuring a perfect fit for every project.

Despite these disadvantages, welded wire mesh remains a popular choice for a wide range of applications due to its strength, durability, and cost-effectiveness. With Beifang's custom solutions, clients can overcome the limitations of traditional welded wire mesh and unlock new possibilities for their projects. From corrosion resistance to customizability and ease of installation, Beifang's custom 2x2 galvanized steel welded wire mesh offers unmatched performance and reliability, making it the preferred choice for discerning professionals worldwide.

In conclusion, while welded wire mesh may have its drawbacks, Beifang's custom solutions redefine industry standards, offering superior quality, performance, and versatility. With Beifang as your trusted partner, you can confidently tackle any project knowing that you have access to innovative solutions that exceed expectations and deliver lasting value.