What are the disadvantages of welded wire mesh

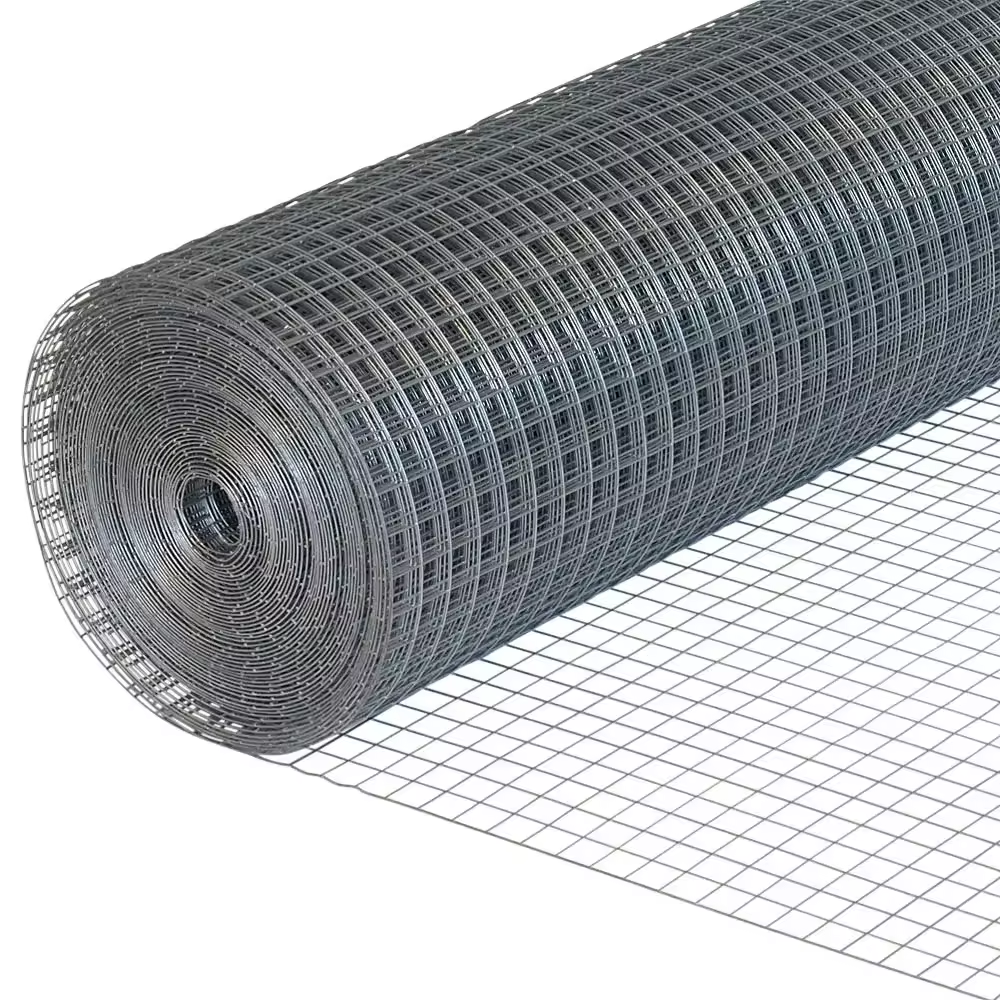

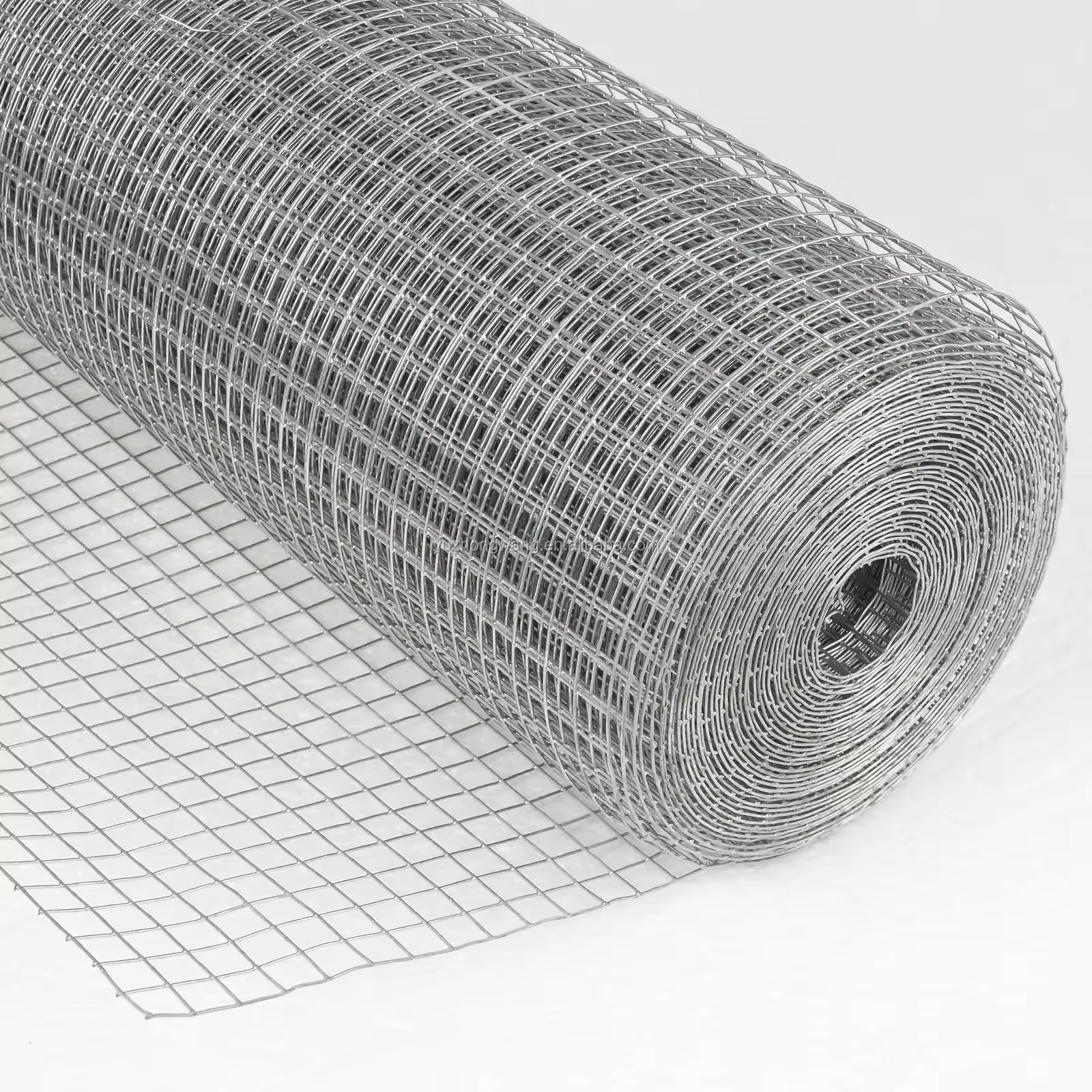

In the world of construction and infrastructure, welded wire mesh plays a vital role in ensuring structural integrity and safety. Northern Transportation, a leading name in the industry, consistently seeks superior materials to meet its stringent standards. However, while Stainless Steel No. 8 electro-galvanized welded wire mesh offers several advantages, it also comes with its own set of limitations.

1. Corrosion Susceptibility: Despite its electro-galvanized coating, stainless steel wire mesh remains vulnerable to corrosion, especially in harsh environments where exposure to moisture, chemicals, or salt is frequent. This susceptibility can compromise the durability of structures over time, leading to maintenance issues and potentially compromising safety standards.

2. Weld Integrity Concerns: Welded wire mesh, although robust, may experience welding defects or inconsistencies during the manufacturing process. These imperfections can weaken the overall structure, impacting its load-bearing capacity and structural stability. Northern Transportation emphasizes reliability in all its materials, making weld integrity a crucial factor in material selection.

3. Limited Aesthetic Appeal: While functionality is paramount, aesthetics also play a significant role, particularly in architectural projects or public spaces. Stainless Steel No. 8 electro-galvanized welded wire mesh may lack the desired visual appeal compared to other finishes or materials, potentially limiting its suitability for projects where aesthetics are a priority.

4. Cost Considerations: While stainless steel offers excellent durability and resistance to corrosion, it often comes with a higher price tag compared to alternative materials. For Northern Transportation, cost-effectiveness is a key consideration in material procurement, necessitating a careful balance between quality and affordability.

5. Installation Challenges: Welded wire mesh installation requires precision and expertise to ensure proper alignment and structural integrity. Complex installation procedures can lead to delays and increased labor costs, posing challenges for Northern Transportation's project timelines and budgets.

6. Environmental Impact: The production process of stainless steel wire mesh, particularly electro-galvanization, may have environmental implications due to energy consumption and emissions. As sustainability becomes increasingly important in the construction industry, Northern Transportation must evaluate the environmental footprint of its materials and processes.

Despite these limitations, Stainless Steel No. 8 electro-galvanized welded wire mesh offers notable advantages, including high tensile strength, resistance to impact, and suitability for various applications. Northern Transportation continues to assess and innovate, seeking solutions that align with its commitment to quality, durability, and safety.

While Stainless Steel No. 8 electro-galvanized welded wire mesh presents certain disadvantages for Northern Transportation's specific needs, its overall performance and suitability depend on various project requirements and considerations. By understanding these limitations and leveraging the strengths of alternative materials, Northern Transportation remains poised to deliver exceptional results in its endeavors.